What is EPS Production and How Does it Work?

EPS Production is a process of producing expanded polystyrene (EPS) products. It involves the use of an EPS pre-expander machine to expand the raw material into a foam that can be used for various applications. The process is relatively simple and cost-effective, making it an attractive option for businesses looking to produce EPS products.

The first step in the EPS production process is to feed the raw material into the pre-expander machine. This machine then heats and expands the material(EPS resins), creating a foam that can be moulded into various shapes and sizes. Once this foam has been foamed, it can then be cut or shaped according to customer specifications. Finally, it is packaged and shipped off to its destination.

EPS production is becoming increasingly popular as businesses look for ways to reduce costs while still producing quality products. With its economic and easy setup, it’s no wonder why so many companies are turning to this method of production!

The Benefits of Using a Batch EPS Pre-Expander in Your Production Line

Setting up a foam bead plant or factory can be a daunting task. But with the help of a batch EPS Pre-Expander, you can make the process much easier and more efficient. A batach EPS Pre-Expander is a machine that helps to expand polystyrene beads into larger pieces of foam, which can then be used in various production lines. This machine is essential for any production line setup as it helps to reduce costs and increase efficiency. It also ensures that the quality of the foam produced is consistent and reliable. With a Sutuan EPS Pre-Expander, you can save time and money while ensuring that your production line runs smoothly and efficiently. Because as we knew, you will need one more experienced production operator to control expanding if you adopted a continuous pre-expander. And the quality of EPS beads is depended on the expert’s skill.

How to Set Up an Efficient and Cost Effective EPS Production Line

Setting up an efficient and cost effective EPS production line is a great way to increase your business’s productivity and profitability. With the right setup, you can produce high-quality foam beads that are used in a variety of applications. This guide will provide you with the necessary steps to set up an EPS production line, from setting up a foam bead plant to setting up a foam bead factory. We will also discuss the use cases of EPS production lines and how they can help you save money while producing quality products.

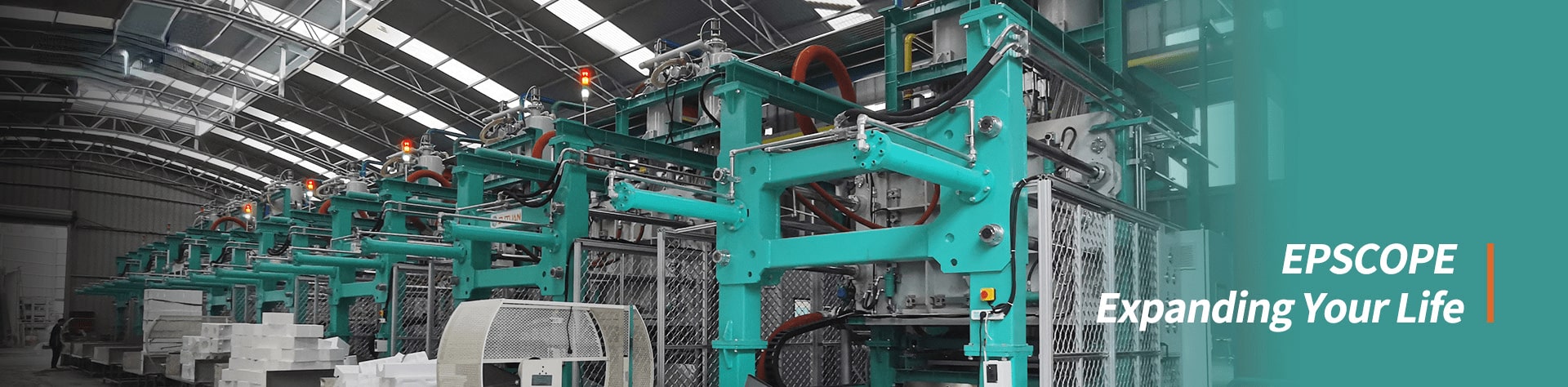

What are the Different Types of Machines Used in an EPS Production Line?

EPS production lines are becoming increasingly popular in the manufacturing industry. They are used to produce a wide range of products, from packaging materials to insulation boards. To ensure that the production process is efficient and cost-effective, it is important to use the right machines for each step of the process.

The most common machines used in an EPS production line include eps cutting machines, eps block moulding machines, and automatic vacuum forming machines. These machines help to cut and shape the EPS material into various shapes and sizes according to customer requirements. Additionally, they can also be used for other processes such as lamination or coating. With these machines, manufacturers can produce high-quality products with minimal effort and cost.