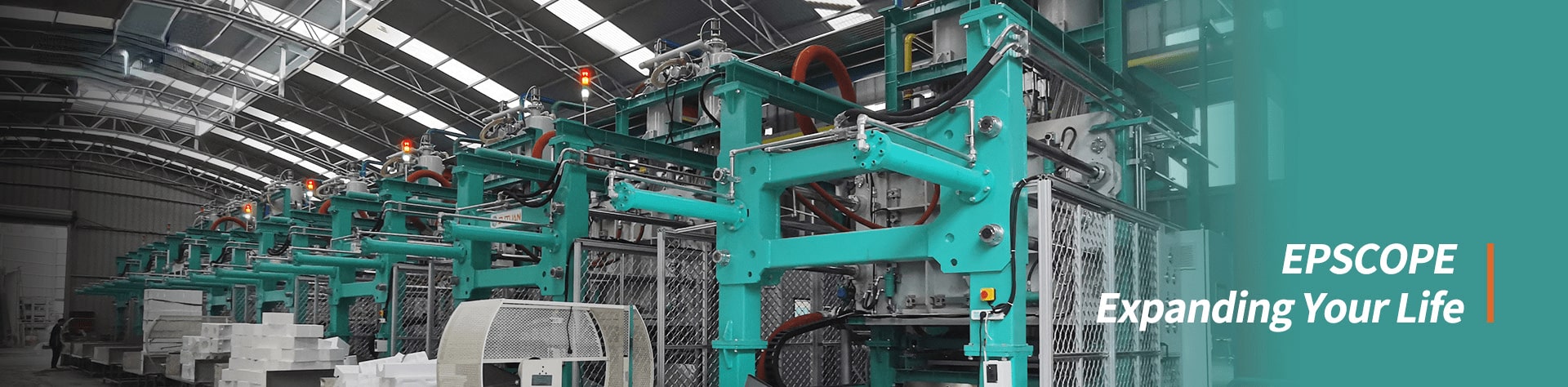

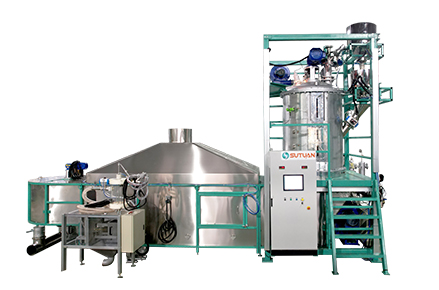

EPS Batch Pre-expander with Recycling System丨EPSCOPE

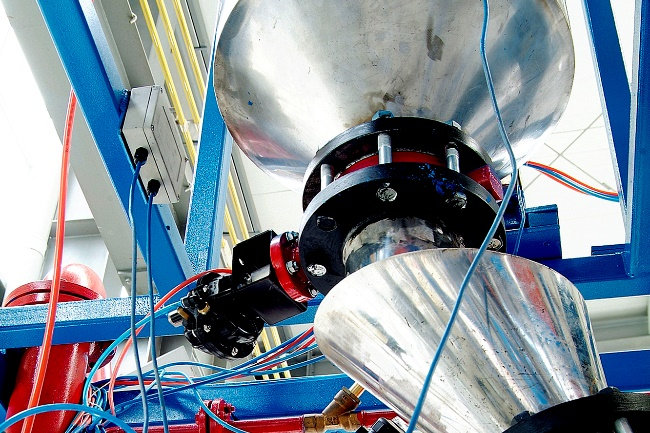

The Styrofoam Batch Pre-expansion Machine adopts PLC programmable control and touch screen control. After the raw material is added to the inside of the vertical tank, the cold air is removed by steam; while the particles are stirred by the agitator, more steam is added until the required air pressure value is reached. As the level of the expanding material of the particle rises, the particle will be expelled after the degree of expansion of the particle is reached, or the time is used to control the pre-exposure. The pressure in the batch pre-expander exceeds the atmospheric pressure, so the temperature of the steam exceeds 100 degrees.