EPS module self-built house, this is a composite wall self-built house with polystyrene foam cavity board as the inner and outer insulation layer of the house wall, and a reinforced concrete bearing layer is poured in the cavity. It has simple construction process, fast construction speed, high thermal insulation performance, good earthquake resistance and low price. It is a rural self-built house model vigorously promoted by the Ministry of Construction!

First, let’s talk about the performance of EPS templates.

1. Good thermal insulation performance and energy saving.

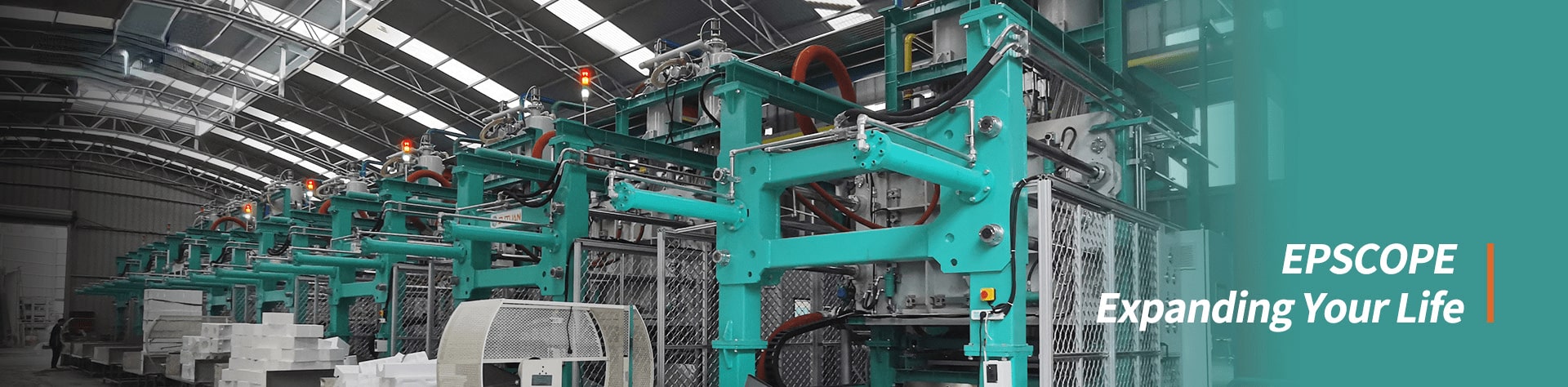

EPS template is a polystyrene foam profile or component with a closed-cell structure, which is made by heating and foaming expandable polystyrene beads and one-time molding through factory standardized production equipment.

Its biggest feature is its superior thermal insulation performance. The inner and outer two layers of insulation boards have a thickness of 5cm each. After pouring the reinforced concrete, the thermal conductivity of the entire composite wall is only 0.03. The wall with a thickness of 25cm is equivalent to the thermal insulation effect of a 3.2m thick brick wall!

In the severe winter, when the outdoor temperature is -5 degrees Celsius, the indoor temperature can be maintained at 10 degrees Celsius; in summer, when the outdoor temperature is 33 degrees Celsius, the indoor temperature can be maintained at 26 degrees Celsius. This greatly reduces the energy consumption for heating and cooling, and plays an important role in the sustainable development of energy and environmental protection!

2. The EPS template has strong carrying capacity!

After being processed by a special production process, the carrying capacity of the EPS formwork is strengthened, which is several times that of the ordinary polystyrene board.

3. Seamless installation, simple and fast!

EPS formwork components have various shapes and sizes, adapting to different shapes of the wall. On each component, there are sockets and tongues around the four sides, and there are evenly distributed dovetail grooves on the inner and outer surfaces, which meet the requirements of building modulus and energy-saving standards, and are organically combined with the building structure, construction method and manufacturing process. In the construction process, as long as the direction is aligned, the concave and convex grooves on the surface can be used to achieve a perfect seamless lap joint, avoiding the slurry running during the concrete pouring process and ensuring the strength of the concrete.

4. Good fire performance.

The EPS formwork itself has been treated with fire and flame retardant. After the main structure is completed, there will be a mortar layer on the inner and outer walls, which greatly improves its fire resistance. That is, it is difficult to catch fire in the air or under the action of high temperature, and it is not easy to spread quickly, and the combustion stops immediately when the fire source is removed!

Second, the construction speed is fast, twice as fast as the brick-concrete structure house!

1. The wall is poured in layers, and there is no need to wait for concrete curing.

The height of each wall module is 30cm. Generally, concrete is poured after 2~3 layers of modules are installed. After the concrete is poured, the modules can continue to be installed upwards. There is no need to wait for the concrete curing to complete the module installation of the next layer, which speeds up the construction. speed!

2. Special roof insulation template, easy to install!

When the roof is constructed, traditional reinforced concrete cast-in-place slabs can be used, or special EPS insulation boards can be used. Square steel is inserted into the cavity to connect with adjacent modules, and the construction is very fast. Then do the waterproofing and tile roofing construction, and the whole roofing project is completed!

The prefabricated construction method of EPS house walls and roofs has zeroed out the masonry work, which has greatly reduced labor costs and accelerated the construction speed. The entire construction period is very short. The construction period of a 200-square-meter two-story villa will not even exceed one month, which is at least twice as fast as that of a brick-concrete structure house!

Third, the structure has strong integrity and can resist earthquakes of magnitude 8!

The floor slab is the same as the traditional frame structure house. It adopts the cast-in-place reinforced concrete floor slab, which is connected with the wall concrete through the reserved steel bars.

Fourth, it is 15% cheaper than traditional houses!

Compared with the traditional brick-concrete structure house, its price is lower. Taking a 200㎡ two-story country villa rough house as an example, the comprehensive unit price of its materials is about 735 yuan/㎡; the labor cost is quite cheap, only about 150 yuan/㎡, which is less than 40% of the brick-concrete structure! A total of 735+150=885 yuan/㎡, which is about 15% cheaper than the brick-concrete structure!