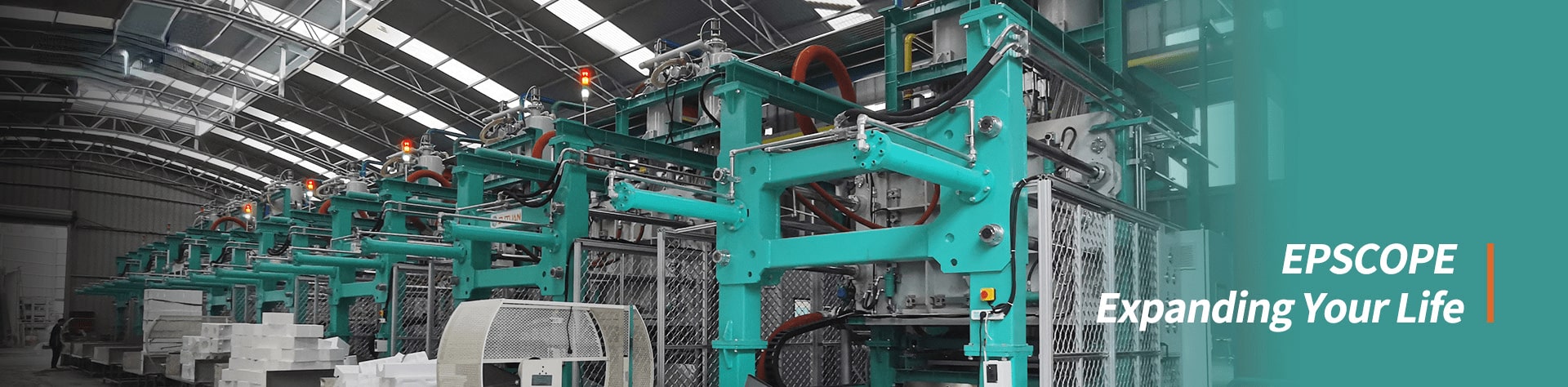

EPS Stainless Steel Bag Silo

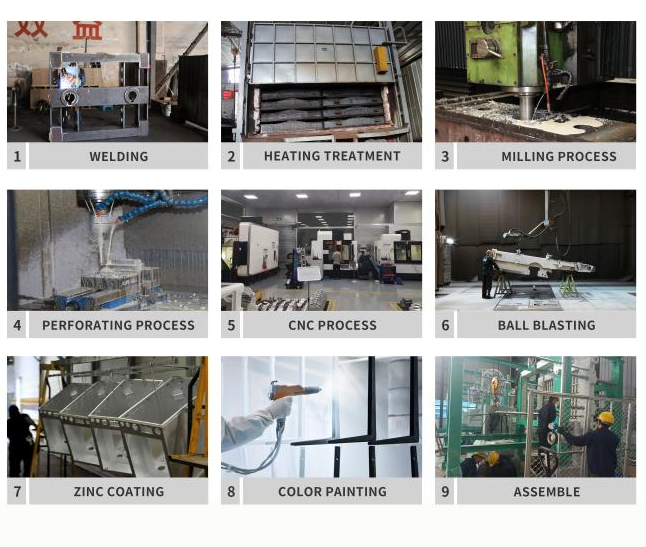

After the eps expansion completing, the demand is matured in the silo, so that the particles can be in contact with the air after the eps expansion. And the equilibrium pressure is established between the air and the interior, so that the pentane content in the particles is kept constant, which is more favorable for eps molding production. Then the design concept of the unmanned factory is to realize the unmanned operation of the whole factory. The curing chamber in the foaming process needs to realize the connection of intelligent control, the automatic curing chamber system can be realized through the set running program.