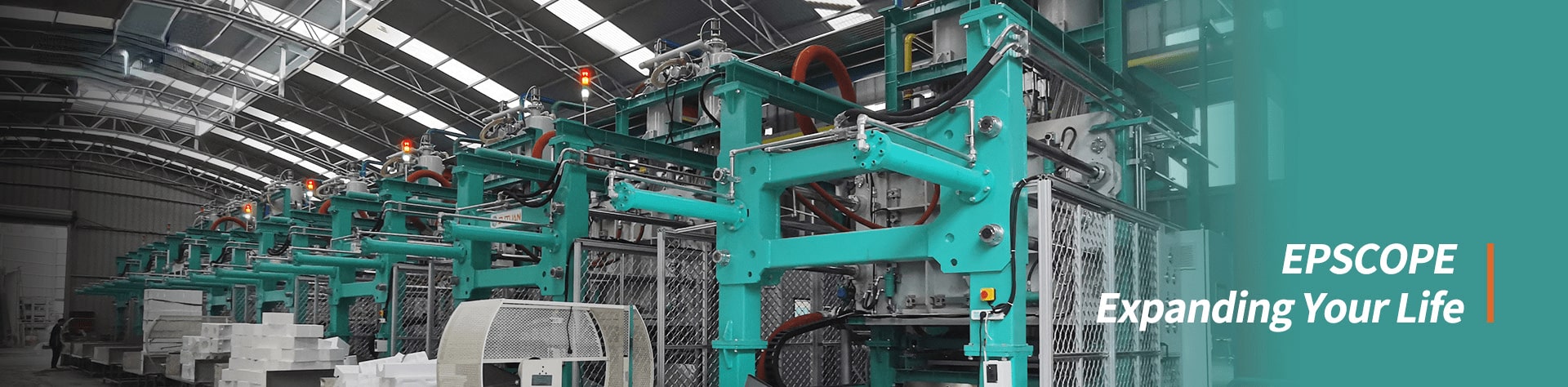

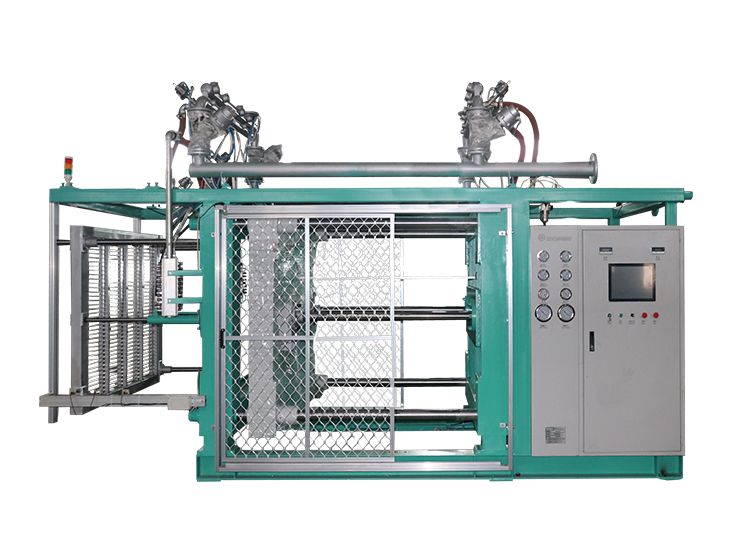

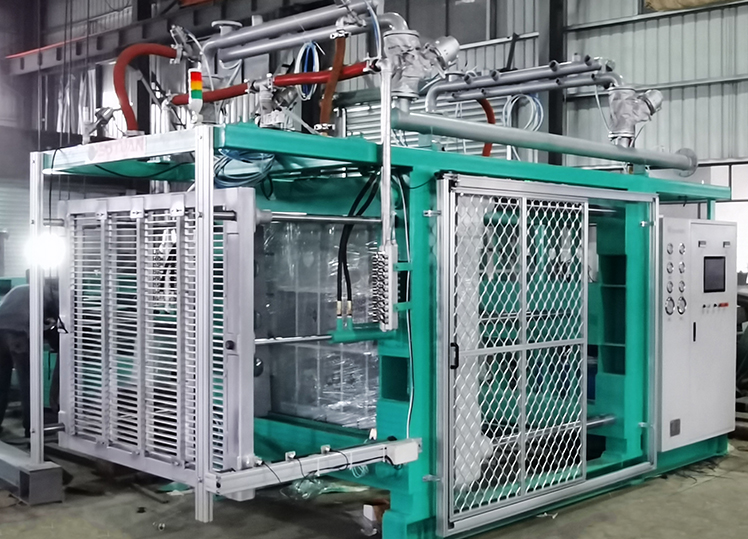

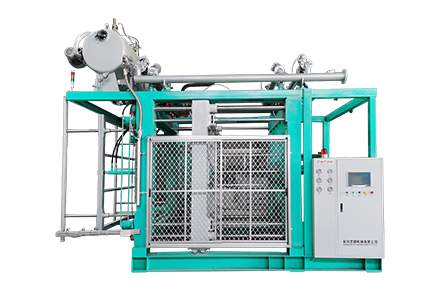

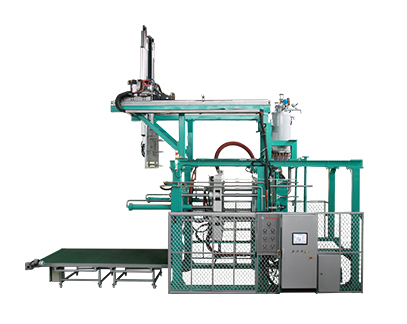

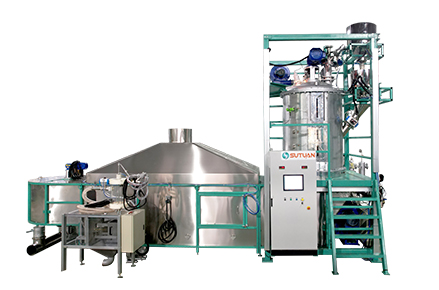

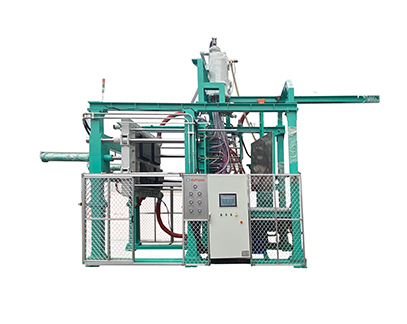

Typical EPS Shape Moulding Machine

Energy Saving Styrofoam Shape Moulding Machine adopts a heat insulation die cavity system to reduce heat loss of die cavity in the heating process and repeated heat wastes and has wide application in the market, which have features of economy, convenient operation and easy maintenance. As the name shows, the machine could save a lot of energy during a year which finally could save the money.