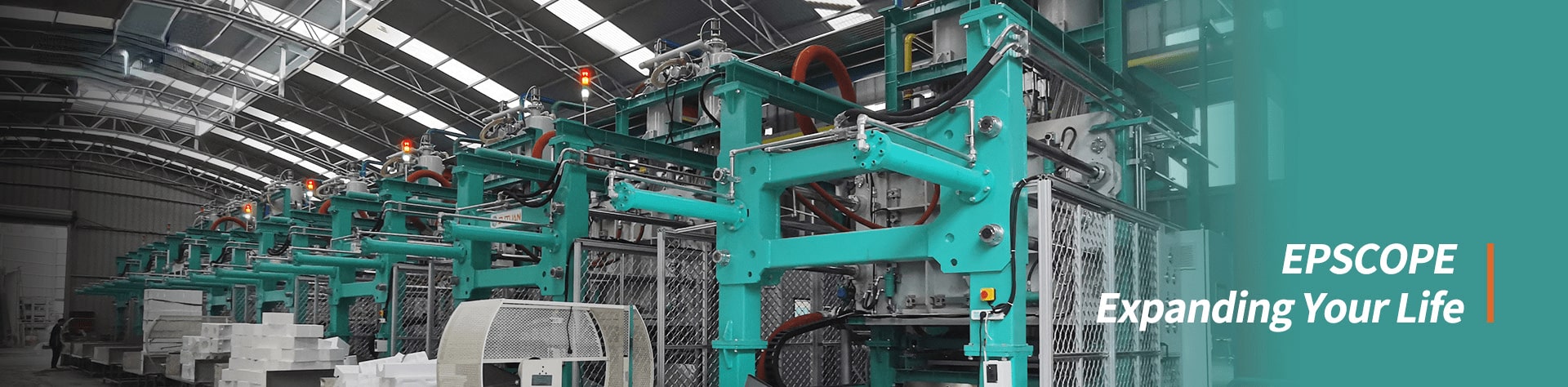

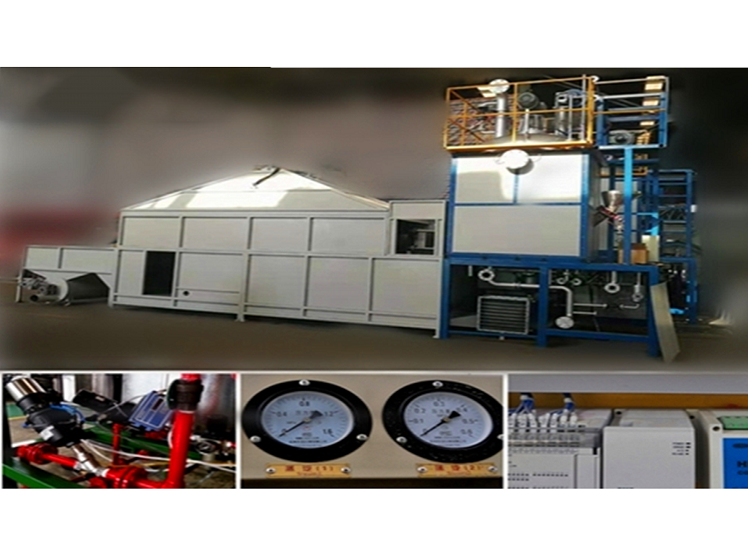

EPS De-duster Machine

The eps de-duster machine separates the eps blocks at the joints, and after being crushed, the sieved particles are uniform in particle size, full, and less dusty, and are mixed with fresh pre-formed granules to be molded again to form eps products of various specifications. The quality of the final reworked eps product is directly related to the dust of the granules, so it is necessary to use a dust remover. The role of the dust remover is to remove dust and particles from the regrind.