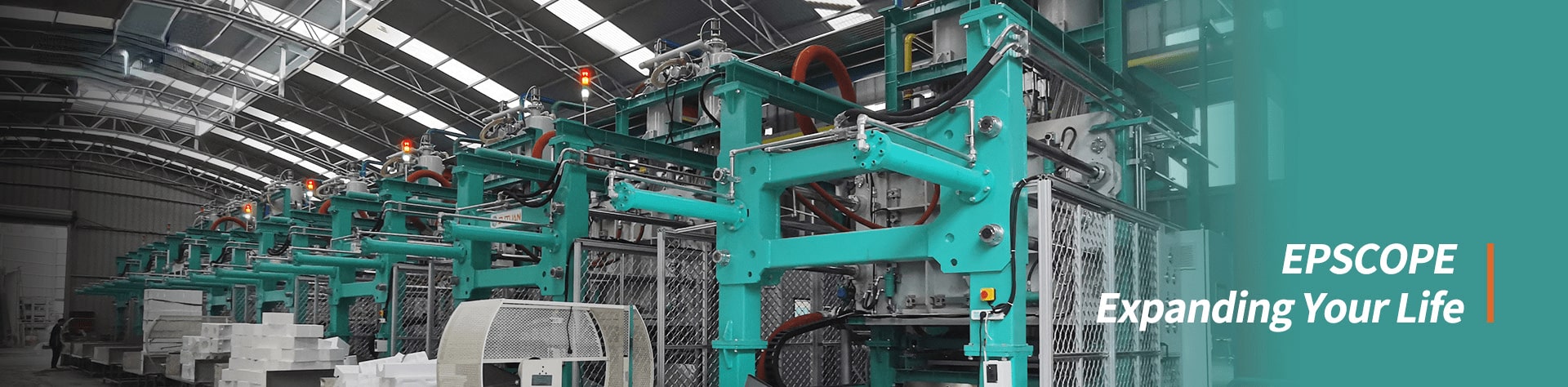

SUTUAN MACHINERY CLIENT CASE – NO HEATING ROOM REQUIRED EPS APPLIANCE PACKAGE PRODUCTION LINE

We recently worked with a client on a turnkey production line project and one of the main features of their equipment was the ability to produce EPS products with low water content. This allowed them to pack their appliance packages directly without the need for additional drying, saving them time and money.

Our team of experts designed and installed a complete production line, which included our state-of-the-art shape moulding machine with a guide rail of mould and a one-button exchange mould system. Our SMED (single minute exchange of die) series of shape moulding machines allowed for quick and easy mould changes, reducing downtime and increasing production efficiency.

But the standout feature of this production line was the low water content of the EPS products. By carefully controlling the heating and cooling process, our machines were able to produce high-quality EPS products with low water content, which is crucial for the packaging of appliances.

With traditional EPS production methods, the products are often too moist for immediate packaging and require additional drying, which can add significant time and cost to the production process. But with our equipment and expertise, we were able to produce EPS products with low water content, allowing our client to streamline their production process and save on costs.

We take pride in our ability to provide turnkey solutions to our clients, and this project was no exception. Our team worked closely with the client to understand their unique needs and challenges and designed a production line that would not only meet their requirements but exceed their expectations.

If you’re interested in learning more about our turnkey production line solutions or how we can help you with your EPS production needs, please visit our website or contact us directly.

The Pictures of Client’s Factory

Watching by Youtube.com