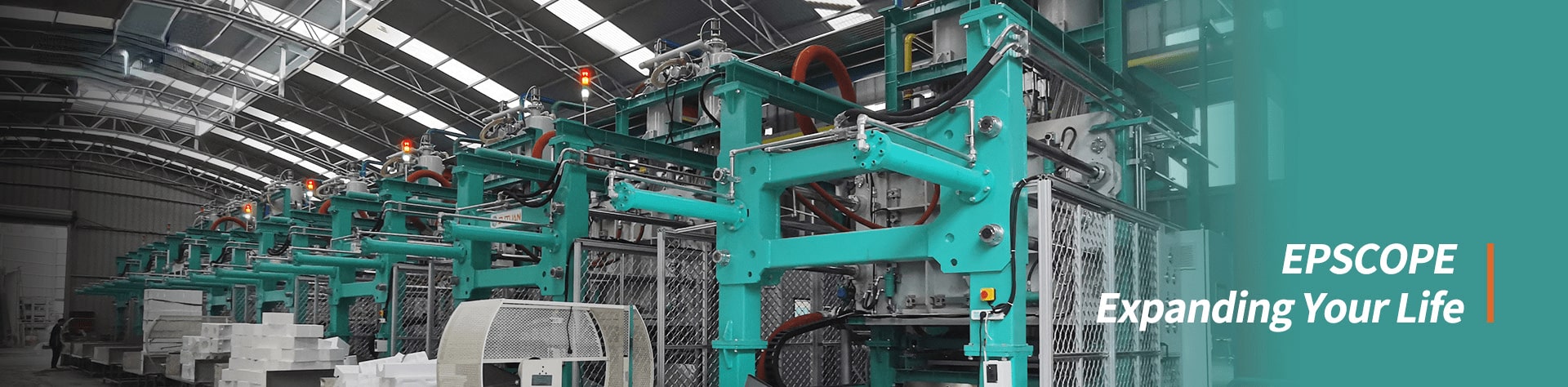

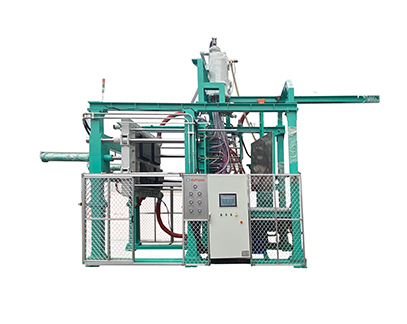

Semi Auto Sandwich Panel Machine

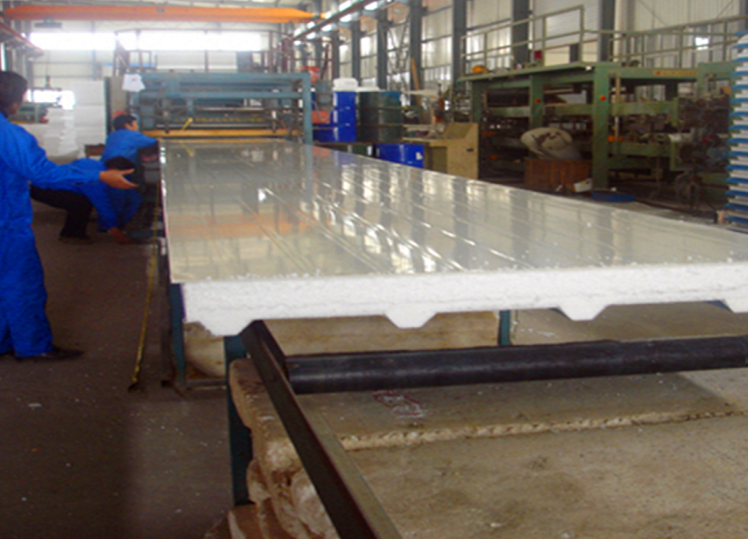

The advantage of semi auto sandwich panel machine is that it can quickly produce high-quality color steel composite panels, saving time and manpower. A production line needs 5 people to complete the operation, which is convenient for the need to meet the construction period. The service life of the equipment is long. The color steel sandwich panel is made up of two layers of color coated steel sheets as the surface layer. The materials with both rigidity and heat preservation and low strength, such as rigid foam, rock wool board and other moisturizing materials, are used as core materials.