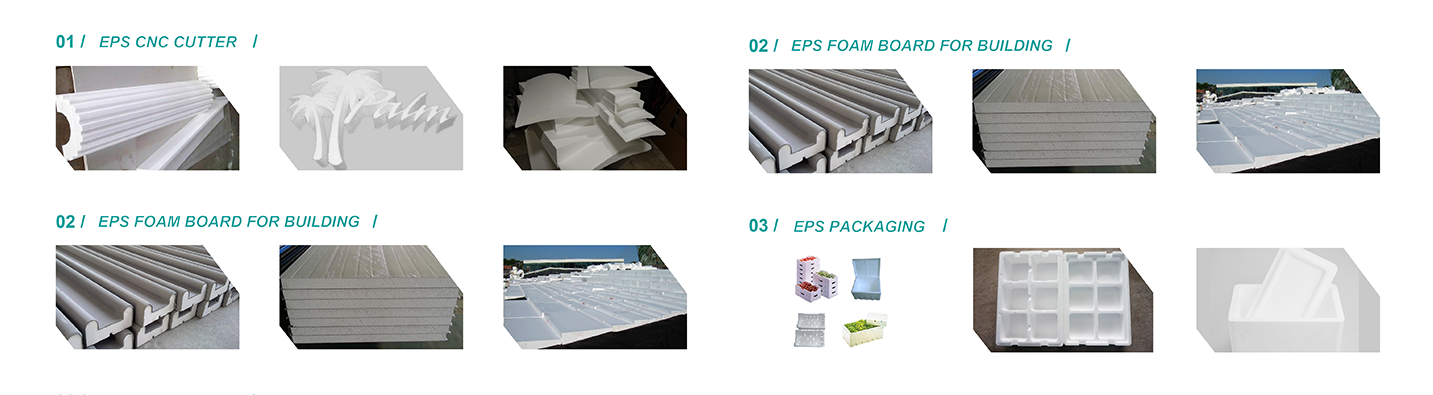

1. Has Moisture-Pro Of Function: The polystyrene produced by EPS Pre-expander Machine has the function of preventing moisture, and the polystyrene can maintain its original strength and shape after long-term use. In addition, the tightly closed container and lid can effectively prevent temperature loss and maintain the ideal temperature.

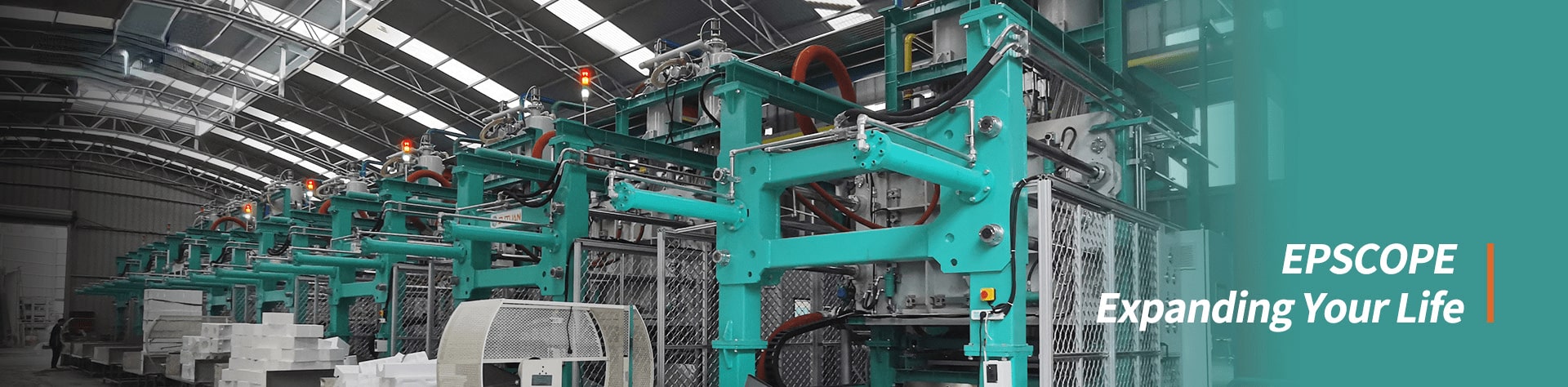

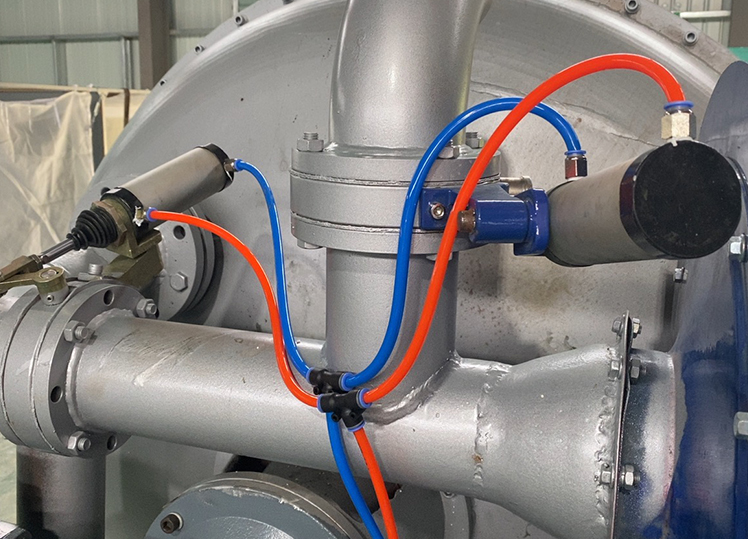

2. Has To Cushion Polystyrene packaging can provide better protection properties. EPS Pre-expander Machine can produce a specific shape and then customize it to the product or part that needs to be protected, maximizing the excellent cushioning properties of polystyrene. EPS Pre-expander Machine produces polystyrene in many industries such as automated processing equipment. The polystyrene produced by the EPS Pre-expander Machine can provide excellent insulation quality; of course, this helps to keep food at the best eating or drinking temperature for the time. In addition, polystyrene can keep hot food at a level suitable for video storage. Temperature, and it is very convenient to use.

3. Meet Sanitary Requirements Many test data show that disposable water cups and dinner plates made of polystyrene are more hygienic than reusable water cups and dinner plates. Many health agencies responsible for overseeing the food service operations of schools, hospitals, and restaurants have recognized the advantages of water cups and dinner plates made of polystyrene. In addition, health organizations in many countries have called for disposable water cups and dinner plates made of environmentally friendly polystyrene. This shows the profit prospects of the EPS Pre-expander Machine market. 4. High-Cost Performance Polystyrene food packaging products are more economical and cheaper than paper food packaging or food packaging that requires cleaning. It can save product washing costs and labour costs. In addition, today’s busy lifestyle requires affordable and fast take-out meals. Polystyrene packaging can provide economical and high-quality food packaging and reduce food packaging costs for catering manufacturers. The market profit of EPS Pre-expander Machine can already be imagined!

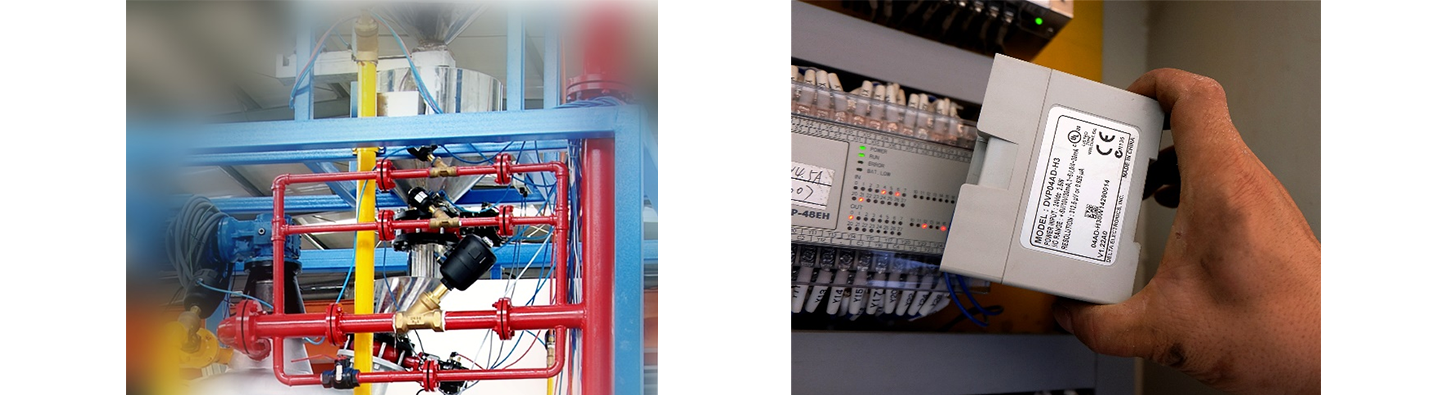

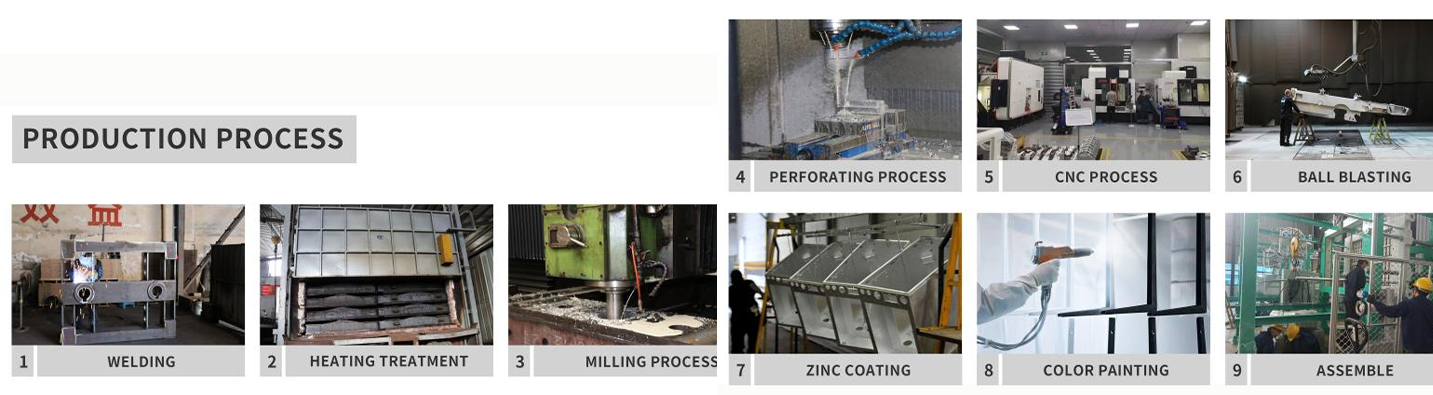

Hangzhou Sutuan Machinery Co., Ltd. has also gained a relatively high market share in the world market by providing EPS Pre-expander Machine. The EPS Pre-expander Machine we provide has a wide range of uses and is suitable for many industries. Sutuan Machinery’s EPS Pre-expander Machine product developers use cutting-edge technology and original quality components to produce it. In addition, our product development team is always customer-oriented and can complete the delivery of the EPS Pre-expander Machine within the time promised to the customer.